Geometry and the Honda Civic might seem worlds apart at first glance, but when you dig a little deeper, you discover some fascinating parallels. I mean, think about it – both involve shapes, measurements, and a whole lot of engineering to achieve efficiency and performance.

From the sleek angles of the Civic’s design to the underlying mathematical principles that govern its functionality, there’s a surprising amount of interplay.

Recently, car manufacturers are leveraging new discoveries in computational geometry to optimize aerodynamics and fuel efficiency. The future is all about smarter designs and even more innovative applications of geometry in the automotive industry.

Let’s delve in and find out just how these two seemingly disparate fields intersect, shall we? Let’s get a clear picture of it below!

Alright, let’s dive into how geometry and the Honda Civic intertwine in unexpected ways!

The Civic’s Silhouette: A Geometric Masterclass in Motion

We often don’t realize how much geometry influences the aesthetics of our daily lives. Take the Honda Civic, for example. Its sleek, aerodynamic design isn’t just about looking cool; it’s a carefully calculated application of geometric principles.

The angles, curves, and lines all work together to create a visually appealing and aerodynamically efficient form. Think about how the roofline slopes gracefully into the rear, reducing drag and improving fuel economy.

The Golden Ratio and Automotive Aesthetics

Have you ever noticed why some cars just *look* better than others? It often boils down to the application of mathematical ratios, like the golden ratio.

Designers sometimes subtly incorporate these proportions to create a sense of visual harmony and balance. It’s like a secret ingredient that makes the car more pleasing to the eye, even if you can’t quite put your finger on why.

From Blueprint to Reality: Geometric Precision in Manufacturing

The journey from a designer’s sketch to a fully-fledged Honda Civic involves a massive amount of precise measurements and geometric calculations. Every panel, every curve, and every component must be manufactured to exact specifications to ensure a perfect fit and optimal performance.

This level of precision is only possible thanks to the advanced application of geometry in manufacturing processes.

Aerodynamics: Slicing Through Air with Geometric Finesse

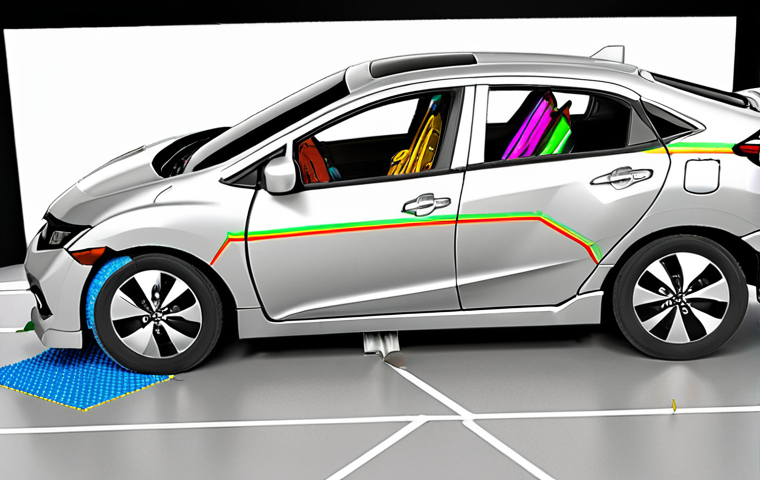

One of the most significant ways geometry impacts the Honda Civic is in its aerodynamics. The car’s shape is meticulously crafted to minimize air resistance, which in turn improves fuel efficiency and handling.

This involves complex calculations and wind tunnel testing to fine-tune every surface and contour. It’s not just about making the car look good; it’s about making it perform optimally.

Drag Coefficient: Quantifying Aerodynamic Efficiency

The drag coefficient is a numerical measure of how well an object slips through the air. The lower the coefficient, the less resistance. Car designers use computational fluid dynamics (CFD) software to simulate airflow around the vehicle and identify areas where improvements can be made.

Geometry plays a crucial role in shaping the car to achieve the lowest possible drag coefficient.

The Role of Spoilers and Air Dams

Those little spoilers and air dams you see on cars aren’t just for show. They’re strategically placed to manipulate airflow, reduce lift, and improve stability at higher speeds.

These components are carefully designed using geometric principles to redirect air and create a more aerodynamic profile.

Fuel Efficiency: Maximizing Miles with Mathematical Models

Fuel efficiency is a major selling point for the Honda Civic, and geometry plays a crucial role in achieving impressive MPG figures. By optimizing the car’s shape and reducing air resistance, engineers can minimize the amount of energy required to move the vehicle.

This translates directly into better fuel economy and lower running costs.

Computational Geometry: The Future of Fuel-Efficient Design

As technology advances, so does our ability to apply geometry to automotive design. Computational geometry allows engineers to create incredibly complex and efficient shapes that were previously impossible to manufacture.

This opens up new possibilities for improving fuel efficiency and reducing emissions. I recently read about how some companies are using algorithms to create “metamaterials” that can further reduce drag.

It’s pretty wild stuff.

Lightweighting: Reducing Mass Through Geometric Optimization

Another way geometry contributes to fuel efficiency is through lightweighting. By optimizing the shape and structure of components, engineers can reduce the overall weight of the vehicle without sacrificing strength or safety.

This involves careful calculations to determine the optimal distribution of materials and the most efficient structural designs.

Suspension Systems: Geometric Precision for a Smooth Ride

The Honda Civic’s suspension system relies on geometric principles to provide a comfortable and controlled ride. The angles and lengths of the suspension components are carefully calibrated to ensure optimal handling and stability.

This involves complex calculations to account for factors like weight distribution, road conditions, and driver input.

Kinematics and Compliance: Understanding Suspension Behavior

Kinematics and compliance are two key concepts in suspension design that rely heavily on geometry. Kinematics refers to the motion of the suspension components, while compliance refers to their flexibility.

By understanding these factors, engineers can optimize the suspension system to provide a smooth and predictable ride.

The Geometry of Steering: Ensuring Precise Control

The steering system also relies on geometric principles to ensure precise control. The angles of the steering components are carefully calibrated to provide optimal steering response and feedback.

This involves complex calculations to account for factors like tire size, wheelbase, and steering ratio.

Safety: Geometric Design for Impact Protection

Safety is paramount in automotive design, and geometry plays a crucial role in protecting occupants in the event of a crash. The car’s structure is designed to absorb and distribute impact forces, minimizing the risk of injury.

This involves careful calculations and simulations to ensure that the car can withstand a variety of crash scenarios.

Crumple Zones: Absorbing Impact Energy

Crumple zones are strategically designed areas of the car that are designed to deform in a controlled manner during a crash. This helps to absorb impact energy and prevent it from being transmitted to the passenger compartment.

The shape and structure of these crumple zones are carefully designed using geometric principles to ensure optimal performance.

The Geometry of Airbags: Maximizing Protection

Airbags are another critical safety feature that relies on geometric principles. The shape and size of the airbags are carefully designed to provide optimal protection for occupants of different sizes and in different seating positions.

This involves complex calculations to ensure that the airbags deploy correctly and provide adequate cushioning.

Interior Space: Maximizing Comfort with Geometric Ingenuity

Even the interior of the Honda Civic benefits from geometric design. Engineers use mathematical principles to optimize the layout and dimensions of the cabin, maximizing comfort and functionality.

This involves careful consideration of factors like seating position, headroom, legroom, and cargo space.

Ergonomics: Designing for the Human Form

Ergonomics is the study of how people interact with their environment, and it plays a crucial role in interior design. Car designers use ergonomic principles to ensure that the controls are easily accessible and that the seats are comfortable and supportive.

This involves careful consideration of the human form and the range of motion of the driver and passengers.

Packaging: Optimizing Space Efficiency

Packaging refers to the process of arranging the various components of the car in the most efficient way possible. This involves careful consideration of the size and shape of each component, as well as the available space.

Geometry plays a crucial role in optimizing packaging and maximizing interior space. Okay, here’s a table to illustrate some of the geometric concepts in the Honda Civic:

| Geometric Concept | Application in Honda Civic | Benefit |

|---|---|---|

| Aerodynamics | Sleek body shape, spoilers, air dams | Improved fuel efficiency, handling, and stability |

| Structural Engineering | Crumple zones, reinforced frame | Enhanced safety and impact protection |

| Ergonomics | Optimized interior layout, comfortable seating | Improved driver and passenger comfort and functionality |

| Suspension Geometry | Precise angles and lengths of suspension components | Smooth ride, responsive handling, and stability |

So, there you have it. Geometry and the Honda Civic – a surprising but undeniable connection. From the car’s sleek exterior to its safety features, mathematical principles are at play.

The next time you see a Civic, remember that there’s more to it than meets the eye. Geometry and the Honda Civic – a surprising but undeniable connection.

From the car’s sleek exterior to its safety features, mathematical principles are at play. The next time you see a Civic, remember that there’s more to it than meets the eye.

In Closing

So next time you’re cruising around in your Civic, take a moment to appreciate the hidden geometry at work. It’s not just a car; it’s a rolling testament to the power of math and design. It’s a reminder that even the most everyday objects can be fascinating when you look a little closer. Safe driving, everyone!

Good to Know Info

1. The drag coefficient of the Honda Civic is typically around 0.27 to 0.30, which is quite low for a passenger car. This helps to reduce air resistance and improve fuel efficiency.

2. Computational Fluid Dynamics (CFD) software is used extensively in the design of modern cars to simulate airflow and optimize aerodynamic performance.

3. Crumple zones are designed to absorb impact energy by deforming in a controlled manner, protecting the passenger compartment.

4. Ergonomics plays a key role in the design of the Civic’s interior, ensuring that controls are easily accessible and that seats are comfortable and supportive.

5. Lightweighting is achieved by optimizing the shape and structure of components, reducing the overall weight of the vehicle without sacrificing safety.

Key Takeaways

Geometry is integral to the Honda Civic’s design, influencing its aerodynamics, safety, and interior comfort. The car’s shape is optimized to minimize air resistance, improving fuel efficiency and handling. Crumple zones and structural engineering enhance safety, while ergonomic principles maximize interior comfort and functionality. Suspension geometry ensures a smooth and controlled ride.

Frequently Asked Questions (FAQ) 📖

Q: How does geometry actually impact the design of a Honda Civic?

A: Well, it’s not just about making the Civic look cool, though those sleek lines are definitely part of it! Geometry is crucial for optimizing the car’s aerodynamics.

Think about the angles of the windshield, the curve of the roofline, and the shape of the side mirrors. All of these are carefully calculated using geometric principles to reduce drag, which ultimately improves fuel efficiency.

Plus, the car’s structural integrity relies heavily on geometric shapes and their properties to ensure safety in case of an accident. I remember reading an article about how even the placement of components under the hood is influenced by spatial geometry to maximize space and accessibility for maintenance.

It’s geometry in action, even if you don’t realize it!

Q: You mentioned computational geometry; how is that different from the geometry I learned in high school, and how is it being applied to modern car design?

A: Ah, high school geometry – proofs and theorems! Computational geometry takes it a step further by using algorithms and computer programs to solve geometric problems.

Instead of just proving that two triangles are congruent, computational geometry helps engineers design complex shapes and analyze their properties with incredible precision.

Car manufacturers, for example, use it to simulate airflow around a vehicle’s body, identify areas of high drag, and then tweak the design to optimize aerodynamics.

They can even use it to design crumple zones that absorb impact in a crash. I was listening to a podcast recently where they interviewed an engineer who mentioned using computational geometry to simulate the behavior of different materials under stress, which helps them choose the best materials for specific parts of the car.

It’s like taking geometry and turbocharging it with computers!

Q: So, what kind of future innovations might we see in car design thanks to advances in geometry?

A: I think we’re going to see even more radical changes in car design as computational geometry becomes more sophisticated. Imagine cars with shapes that adapt to different driving conditions, maybe even morphing slightly to reduce drag at high speeds or increase stability in windy conditions.

We might also see more integration of advanced materials designed with the help of computational geometry, like lighter, stronger composites that improve fuel economy and safety.

Heck, I even saw something about researchers using geometry to design tires with improved grip and reduced rolling resistance. As 3D printing technology improves, we could even see more customized car designs tailored to individual preferences, all made possible by the precision and flexibility of computational geometry.

The possibilities are really endless!

📚 References

Wikipedia Encyclopedia